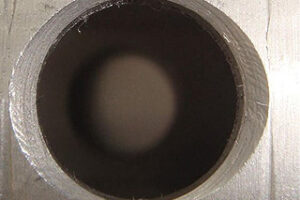

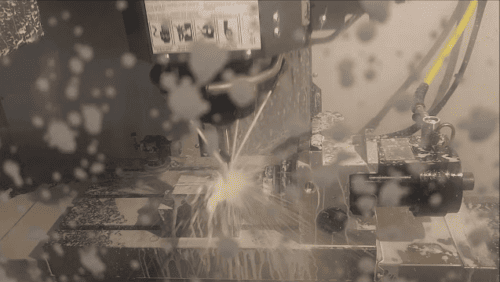

G & J Steel & Tubing, Inc. is a leading provider of tube fabrication services, including tube machining, threading, and boring of holes. We have capabilities in boring, milling, turning, and threading. Machining includes various slot patterns, shapes, notches, chamfers, miter angles, etc.

Putting holes in tubing is critical to being able to offer full service tube fabrication. Forming holes can be difficult and G & J Steel & Tubing has over forty years of experience with this operation.

Whether the holes are on the end of the tube, in the middle, single wall, through holes or multiple holes, we can manufacture your parts to the tightest tolerance.

There are four basic ways to form a hole: drilling, piercing with an arbor, blind punching without an arbor and laser. The hole location, tolerance, allowable wall deformation, burr condition, and volume determine the best manufacturing method for a hole. G & J can produce holes using all of these methods with the appropriate equipment and tooling in the highest production volumes.

For more information on our services, please contact us today.