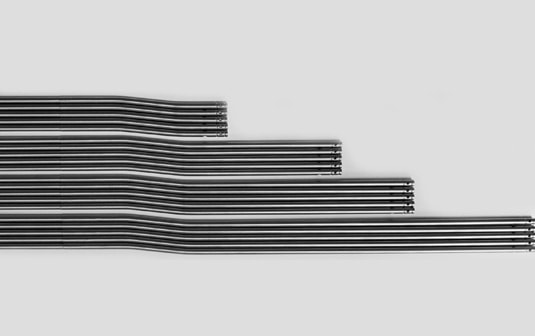

AR-15 GAS TUBE – WHOLESALE MANUFACTURING FOR COMMERCIAL AND MILITARY APPLICATIONS

- Pistols, Carbine, Mids, Rifles

- Special sizes and shapes custom manufactured to your requirements

- Nitride coating available

- Minimum order quantity of 500 pieces, call for pricing

As an established leader in the manufacturing of tube products, our success is built on our ability to meet all of our customers’ requirements. In fact, developing innovative production solutions is part of our culture, and is highlighted in the project shown here. We utilize automation to lower operating costs, increase productivity, and improve quality, passing the savings along to our customers. In many cases this involves the investment of significant capital, or the use of internal resources to develop and integrate systems and processes that deliver the optimal solution for a given product. We have created a number of dedicated work cells to meet the needs of specific part families, these efforts have allowed us to reduce cost, improve quality, and speed delivery.

In this project, our team had to overcome a number of obstacles to deliver a precision process that would meet volume and cost requirements. The customers are manufacturers of firearms for military applications, who require a high volume of gas tubes for several lines of direct impingement firearms. Because of the required volume of 500,000 to 750,000 parts annually, we had to develop a high-speed automated work cell that could perform a number of precision processes.

The first issue we had to overcome was the condition of the raw material. The O.D. tolerance we required for the raw tube was beyond the ability of the mill to meet, so we had to develop a centerless grinding solution that would give us the volume and dimensional accuracy that the project required. Our system met all these demands and also accommodated grinding of the smaller O.D. section that the design called out. It allowed us to work with standard tubing, and eliminated a secondary operation that is typically performed on a lathe.

Another issue we had to deal with was the assembly and grooving of a plug within the tube. We solved this issue by modifying a grooving machine into a dedicated automated solution for the process. The tubes also required two holes, a through-hole and one-wall hole. To meet the high-speed requirements we developed a CNC drilling station that provided fully automated production of burr-free holes. In the end this work cell far exceeded our needs and is able to produce over 1 million holes annually.

Another portion of this project required the bending of a tube that is oriented to the holes drilled in the previous process. The profile required for this tube could not be achieved with any commercially available equipment, so again we had to develop a system specifically for this customers work. The bending system we designed includes an automatic loading feature, an optical orientation system, and dual bending, integrated into a high-speed process that proved to be very accurate, exceeding the tolerance requirements.

All of these innovations, and equipment modifications were integrated into a single fully automated work cell that allowed us to greatly exceed the customer’s expectations for quality and output.

For more information about this project, or the processes and equipment used to manufacture it, contact us directly.