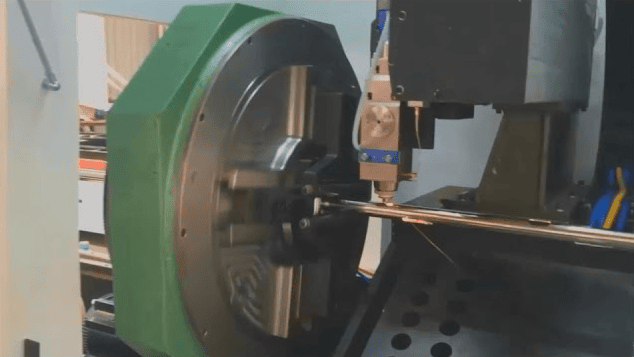

G & J Steel & Tubing, Inc. can perform a wide variety of stamping operations including different slot patterns, flattening, ovalizing, notching, dimpling, tabbing, etc.

Stamping & Laser Cutting

STAMPING & LASER CUTTING SPECIFICATIONS

| Laser Services | Holes Punched Notch End Form Slots Formed |

|

| Hole Diameter | 0.008 Inch and up | |

| Outside Diameter | 0.010 to 3.000 Inch | |

| Wall Thickness | 0.004 to 0.125 Inch | |

| Workable Materials | Aluminum Brass Carbon Steel Copper Cu Ni | Kovar Nickel & Ni Alloys Rodar Stainless Steel Titanium |

| Workpiece Type | Any length or configuration | |

| Tolerance | ± .005 Standard Tighter tolerance available upon request |

|

| Production Rate | 60 to 1000 Pieces per Hour | |

| Production Rate Variables | Length of part, location, and manufacturing method determine production rates. | |

| Cleanliness | Parts cleaned as required based upon hole manufacturing method | |

| Workpiece Length | Any required length | |

| Comment | Based upon the drawing our engineering department will recommend the appropriate method of hole manufacturing | |

| Equipment | Drill presses with single or multiple head drill fixtures Hydraulic punch presses Pneumatic punch presses |

|

| Industries Served | Aerospace & Aircraft Air Compressor Air Conditioner Automotive Beverage Electronics | Engine Gas & Appliance Heat Exchanger OEM Utility (Power/Sewer/Water) |

| Quality Assurance | Cpk 1.67 – 2.0 | |

Get In Touch

G & J Steel accepts your challenge to solve ANY metal tubing problem. Email us drawing and we will get back to you with a quote.

Contact Us Request a Quote